By Seth Gladden

Director of Marketing, Meridian Adhesives Group Flooring Division and Taylor Adhesives

For several articles going forward, we’ll examine many common yet sometimes misunderstood terms. Getting them wrong can cause installers heartache, heartburn, and money. That’s because it’s not enough to speak the language of flooring installation. You’ve got to know what it means, too.

Let’s start with everyone’s favorite topic: moisture. Test your knowledge against these eight terms. If you ace all eight, that’s great! If you miss a few, this has been a worthwhile review!

- RH = Relative Humidity – This is not to be confused with atmospheric relative humidity, although that does play an important part as well (temperature, humidity, air pollutants, dew point, barometric pressure, sunlight, airflow). In the flooring industry, RH testing refers to the process of drilling and placing a test probe in a concrete slab. It measures how much moisture is present in relationship with how much moisture could be present, or in other words, a percentage of saturation. The higher the number, the closer to standing water you get. It is important to remember that this depends on atmospheric conditions and that RH is only a snapshot in time and can change with time and seasons. Remember high-school chemistry? Whether you are a fan of it or not, one of the easiest ways to think of RH is that it is like potential energy (stored), whereas MVER is like kinetic energy (moving).

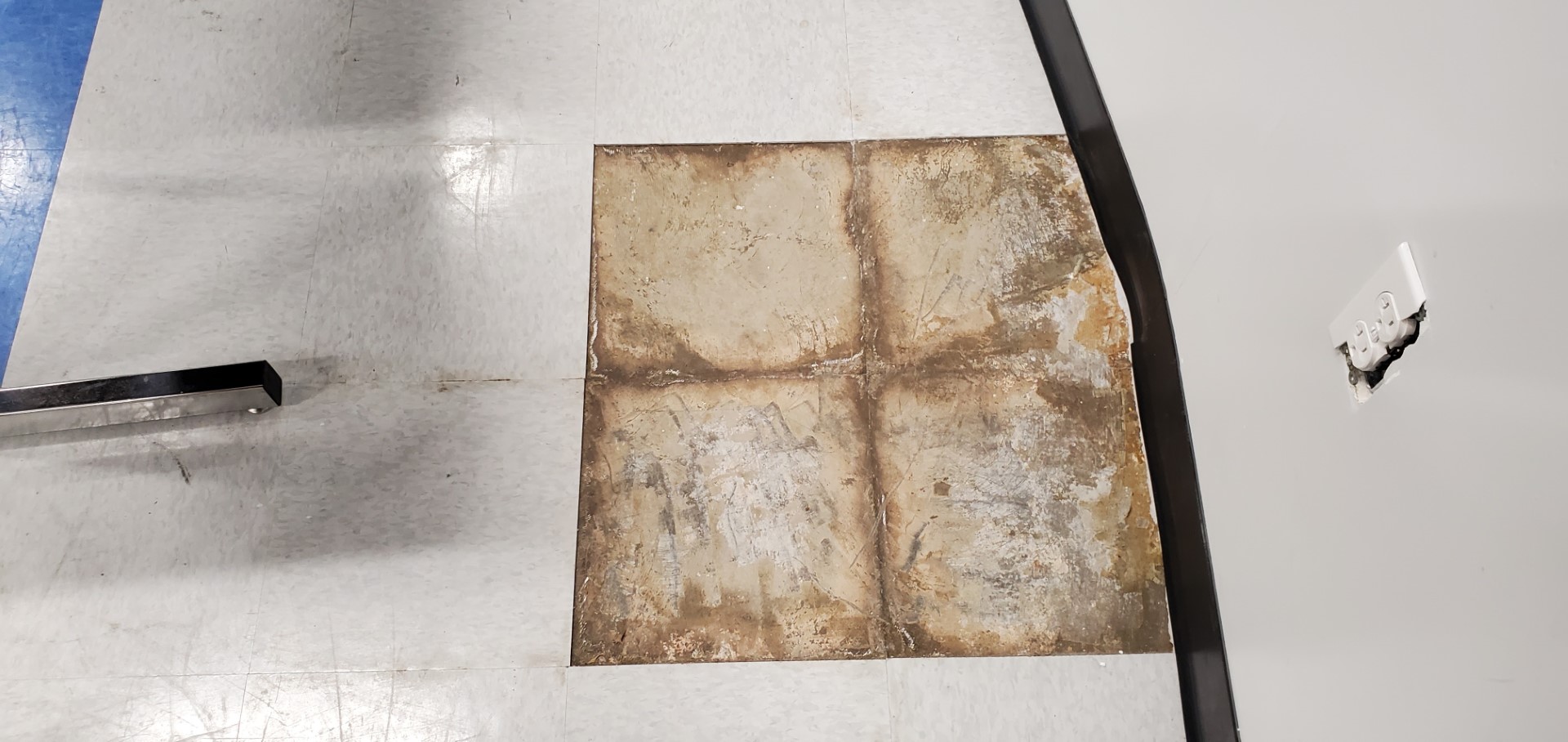

- MVER = Moisture Vapor Emissions Rate – also known as the Calcium Chloride test (CaCl)- a measurement of how much moisture vapor emits from a concrete slab (ASTM F1869). The higher the MVER number, the more moisture is emitting from the slab, which can lead to flooring failures, mold, mildew, and a host of other problems. An MVER of 8 lbs means that eight pounds of water vapor is emitting from every 1000 square feet every 24 hours. Water weighs in at just over eight pounds per gallon, meaning that almost a gallon of water comes out of that 1000 square foot daily.

- pH = A measurement of the acidity, or alkalinity of a substance. As it relates to flooring, this applies primarily to concrete slabs. Newly placed concrete holds a pH of 12-13 on the inside and often 10-11 on the surface. If concrete drops below this healthy internal pH level, the rebar will begin to corrode and the concrete will lose strength and durability, exhibit spalling/cracking, and can lead to complete structural failure. However, higher levels of pH can attack adhesives and even floor covering materials. Be sure the products chosen can withstand or even block unwanted alkalinity. NOTE: pH is measured on a logarithmic scale, meaning that for every number the pH increases, it is ten times more alkaline (ex. pH of 12 is ten times more alkaline than a pH of 11).

- Waterproof Bond = This means that once fully cured, an adhesive will achieve a bond that cannot be broken down or re-emulsified by water alone. However, this does not mean the adhesive provides any protection against moisture. Always check for moisture barrier products vs. moisture tolerant products. Water is a great carrier and can bring high alkalinity (pH) to the surface along with it, so if an adhesive that forms a waterproof bond does re-emulsify, it is typically indicative of a high pH environment.

- Water-Resistant Bond = This is referring to an adhesive that once fully cured, will be resistant to its listed levels of water vapor. However, if exposed to higher levels of water vapor or standing water, these products can lose their tack and lead to a loss of proper bond, likely resulting in a flooring failure.

- ASTM E1745 = This is the “Standard Specification for Plastic Water Vapor Retarders Used in Contact with Soil or Granular Fill under Concrete Slabs,” or as most in the flooring world know it, the requirement of having an intact, sub-slab moisture vapor retarder. Even though it’s considered standard practice in new construction to install sub-slab vapor retarders, older concrete slabs may not have one, especially for 20+ years. Even if an older slab has one, it is likely not intact due to disintegration and time, making it vital to verify if one is present and in good condition. Typically, this requires drilling a core sample and can still give inconclusive results. It is essential to know that most products designed to go over concrete, including patch/level products, adhesives, coatings and primers require an intact, sub-slab vapor retarder be present in order for their warranty to be valid.

- Hydrostatic Pressure = According to Dictionary.com, this is defined as “the pressure exerted by a fluid at equilibrium at a given point within the fluid, due to the force of gravity. Hydrostatic pressure increases proportionately to depth measured from the surface because of the increasing weight of fluid exerting downward force from above”. Despite how scary hydrostatic pressure sounds (and can be), it is actually a very rare problem, although many moisture issues are mistakenly given this label. Essentially, it is pressure in the capillaries and pores of the concrete, being driven through the concrete slab by some external force. The most common culprits leading to hydrostatic pressure are improper drainage or a high-water table. Often, leaky, or broken water pipes are lumped into hydrostatic pressure, however, they are technically considered hydraulic pressure but result in similar issues.

- Moisture Barrier vs Moisture Tolerant Adhesives = This is one of the most widely misunderstood concepts regarding flooring adhesives today. When adhesive manufacturers assign RH, pH, and MVER data points (numbers) to their products, the adhesive can withstand or “tolerate” those levels. However, just because an adhesive can tolerate high moisture (ex. 99% RH, 12 lbs MVER, 12 pH) does not mean the adhesive will offer any moisture protection for the floor covering material being installed. If you are looking for a product that can withstand and block moisture, you need to look for moisture barrier adhesives.

Find out more …

Moisture leads to more flooring-related claims every year than any other source. Check out “The Billion Dollar Question” (TAYLOR TIME LIVE – S1 E1) for straight talk from the experts. And for more information and great advice on a range of adhesives issues, visit www.TaylorAdhesives.com/TaylorTime or our YouTube channel.